Synthotech has a commitment to operate our business in a way that minimises environmental impacts and promotes responsible business practices throughout our organisation.

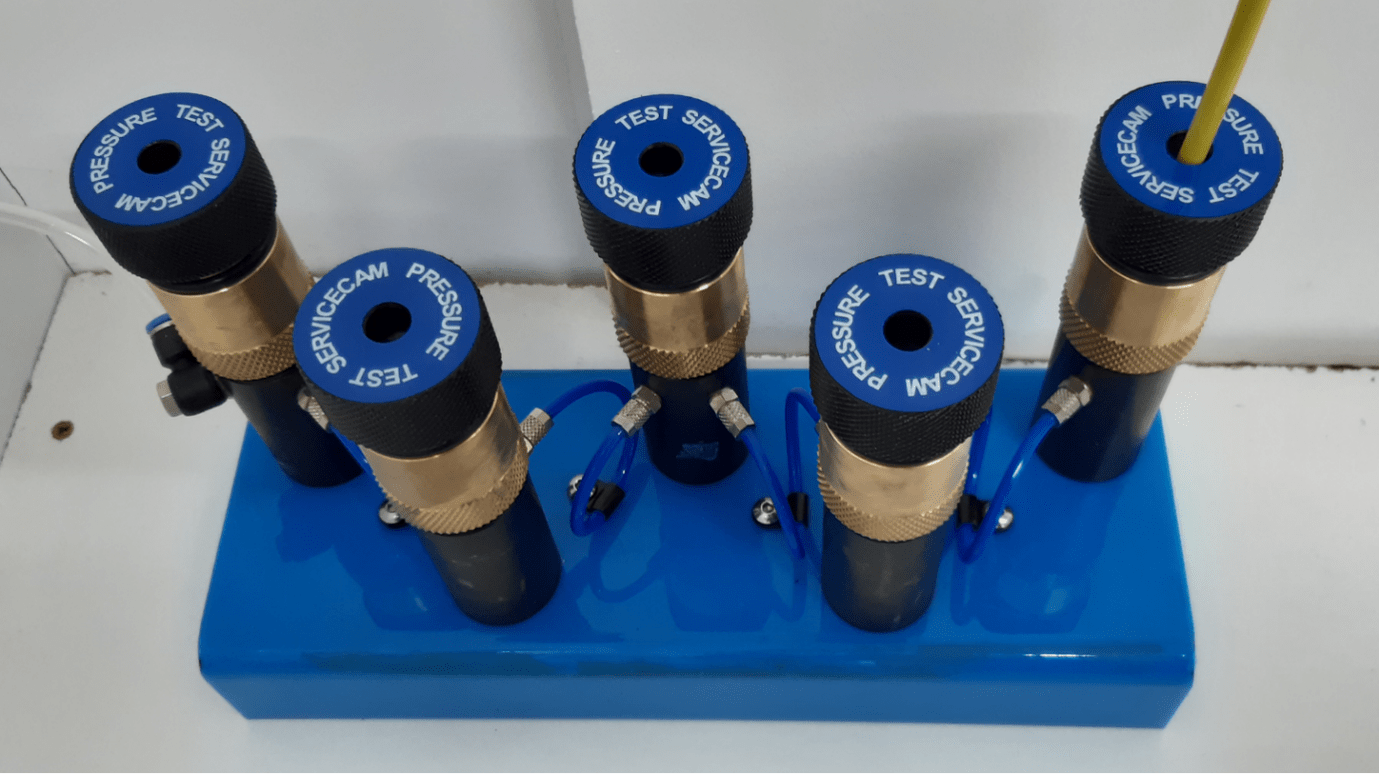

Our strategy has always been to achieve company-wide energy efficiencies and ensure we reduce waste and maximise recycling waste materials. Recently our production team have been using an environmentally friendly way to create a ServiceCAM camera tester, with capabilities of testing up to 5 cameras simultaneously.

The ServiceCAM™ range consists of live access CCTV systems for use in 17.5mm to 55mm PE services. The system can survey up to 20 meters in a single direction and operates in pressures up to 4barg.

The testing unit was created from obsolete products, planned waste and unutilised stock. The base (plastic C profile) had been found after being not being used for some time. Other parts were made from the old stock of a Synthotech system, Sealback. The brass components of the testing rig were made using 1-inch BSP adaptors that were planned to go to waste.

The caps are current stock, as well as the gasket and pneumatic connectors. Ultimately, there was no design process or new purchases needed to create the rig and no extra time was dedicated, meaning our team could continue working as normal. The feedback from the production and SynthoCARE team was excellent, with the green testing equipment being quick and easy to use.

As Synthotech continues to design and manufacture innovative engineering solutions, we hope to put similar practices in place to reduce our impact on the environment.

Does your business have environmentally friendly practices during the production process and the wider departments? We’d love to hear about them! Get in touch with us here.