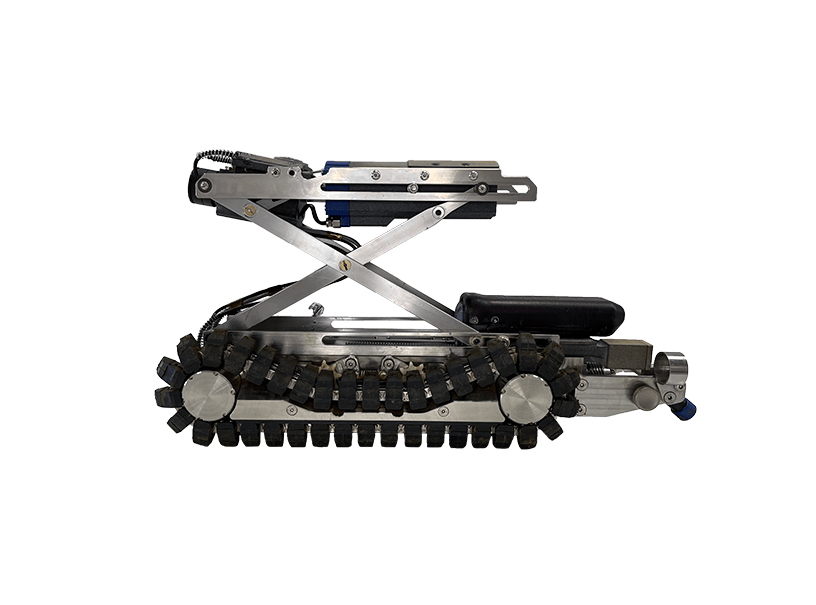

LeakVISION is a patented in-pipe gas leakage detection sensor, mounted to a robot base or push-rod camera system. This innovative system is used for the inspection of in-pipe features to highlight potential areas of interest for leakage from pipeline features, such as joints, connections and defects.

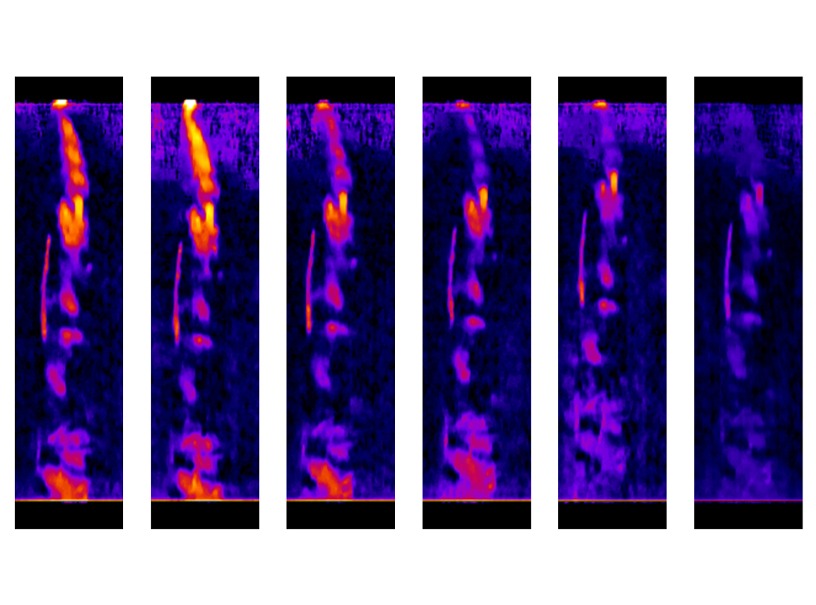

The novel sensor visualises leakage and gives users heat-seeking vision that can home in exactly on the point of leakage. Compared to traditional techniques, LeakVISION gives users much more information in an easy to digest format whilst being quick and easy to deploy on-site, speeding up how leakage is detected and repaired.

The system was developed during a collaborative project alongside Northern Gas Networks and Synovate, whilst also working with the EIC and a consortium of innovators, including ROSEN, The Technology Partnership (TTP) and a range of academics with support from OFGEM NIA.

LeakVISION aims to address the challenge of the traditional method of “above ground bar holing”. This technique can often produce inaccurate results, causing unnecessary excavation and reinstatement works to be carried out. The application of the technique can also be physically demanding and can cause unwanted strains or injury to operatives performing the work.

The LeakVISION solution can increase productivity by locating underground leakage both reactively and proactively. The complex world of underground utility networks creates a challenging environment to find the exact location of any underground leakage.

LeakVISION’s technology makes use of machine learning to analyse and highlight leakage by directly scanning the pipeline and pinpointing the area. This provides improved decision making and very precise targeted remediation, reducing the impact on the environment and road users by preventing and minimising excavation.

Utility networks now have a powerful tool to identify and locate leakages without the need for large excavations. Looking to the future, LeakVISION supports the transition to net-zero. By locating and sealing leakage points, network contribution to greenhouse gas emissions and climate change is greatly reduced.

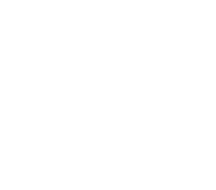

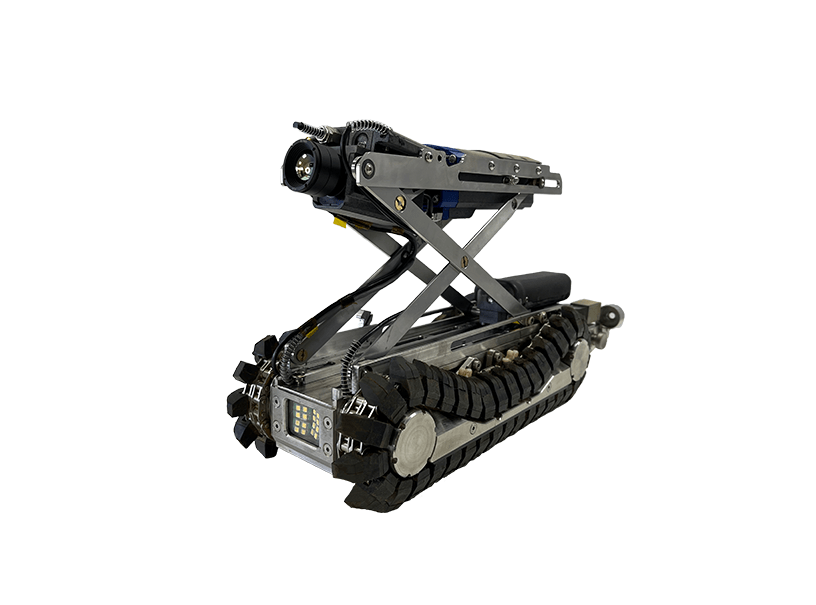

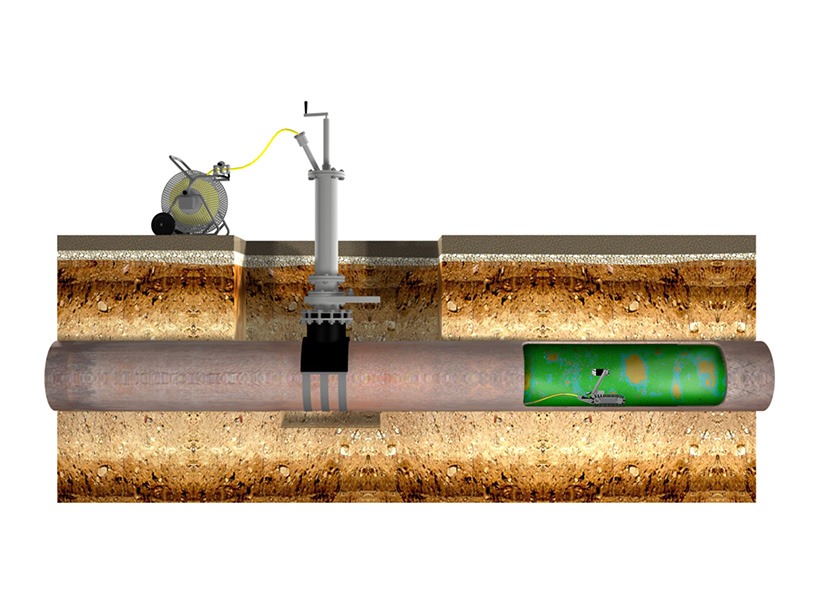

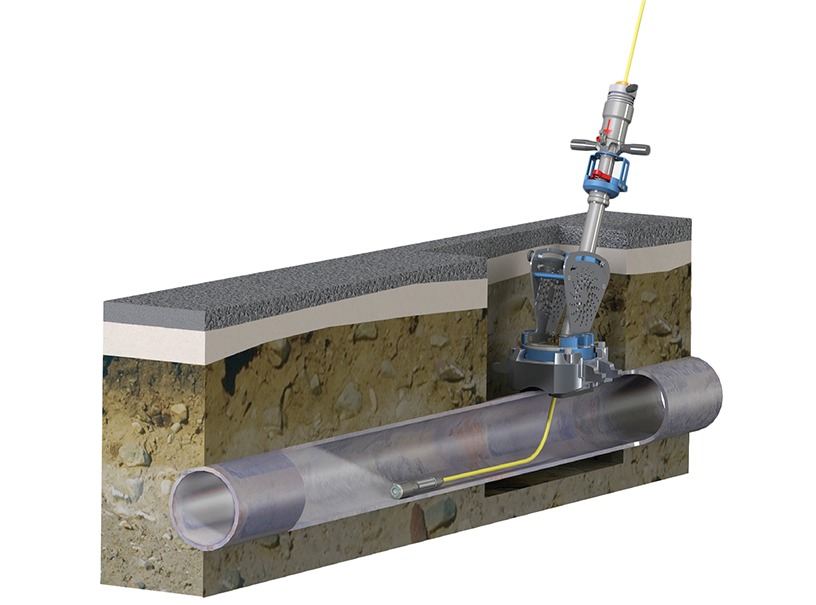

LeakVISION’s technology is flexible for the application needed. The thermal image sensor can be inserted into a pipe via a robotic crawler or push-rod camera depending on the pipe configuration and operational requirements. The LeakVISION system also comes equipped with a display monitor for live pipe viewing.

Key benefits include:

- Reducing the need for excavations, minimising environmental impacts, costs and traffic disruption

- Offers a proactive approach to gas networks maintenance and management

- Machine learning technology allows for pinpoint accuracy and precise targeted remediation

- Provides assurance that underground pipelines are safely maintained and ready for energy transitions as part of a condition assessment process